PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

一、Design principle and performance introduction:

In the early 1980s, foreign scholars pointed out that fiber separation was caused by the buckling of wood fibers under axial compression, that is, when wood fibers were used for axial compression pulping, pulp with long fibers and good binding force could be produced with low energy consumption。Based on this theory, the twin-screw kneading and splitting machine makes the fibers dissociate and fibrillate, and the fibers are cut short to produce high-quality pulp。Its working part is composed of a pair of modular combined screws which are engaged in parallel and rotate in the same direction and a set of semi-open shells with detachable bushings。The shell is provided with a liquid injection hole and a filter for extracting liquid. Spiral parts can be composed of multi-stage slurry conveying area, extrusion area, squeezing, tearing and kneading area, impregnation treatment area and homogenization and mixing area according to process requirements.

1. Spiral propulsion conveying section: raw materials are forcibly and efficiently pushed to the extrusion, kneading and yarn separation area;

2. Extrusion section: increase the compactness of wood chips and bamboo chips, and dehydrate and concentrate at the same time;

3. Squeezing and rolling section: raw materials are squeezed, torn and crushed for fibrosis, and mechanical energy is converted into heat energy, so that the raw materials are heated。

4. Immersion and washing zone: adding liquid medicine and mixing with high concentration, so that slurry and liquid medicine can fully act through friction; If clean water is added, the washing effect can be completed.

二、Structure and composition:

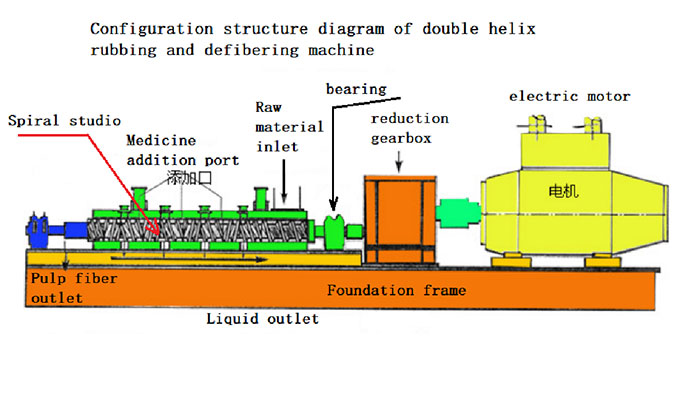

The twin-screw twisting and splitting machine consists of a motor, a special gear box, a combined screw, a semi-open shell, a feeder, a hydraulic system, a lubricating system, a liquid medicine (or water) injection system, a waste liquid recovery system, a stand and the like.

三、The twin-screw extruder can perform the following functions:

3.1. Pulping: The combined shafts of two mutually meshed spiral parts are like an efficient screw pump. During the process of forcibly extruding and conveying raw materials, wood chips, bamboo chips and other raw materials are subjected to greater extrusion force and kneading in the fiber axial direction in the extrusion grinding area, which is beneficial to fiber axial cracking, strengthening the penetration of liquid medicine and fiber separation, and completing the grinding function of pulp。

3.2、Chemical impregnation: This machine can be used for a variety of chemical treatments, and can inject liquid medicine into different working areas of the shell. It is a high-efficiency high-consistency mixer, and the slurry is vigorously kneaded when it passes through the squeezing zone. At the same time, the temperature and pressure can accelerate the chemical reaction of the slurry at high concentration。

3.3、Washing: The machine is equipped with an effective filter in the high pressure area, which can be used to grind chemical mechanical pulp or semi-chemical pulp and wash it at the same time, and multiple washing areas can be set according to the process requirements. High extrusion force and effective kneading can realize efficient washing, and at the same time, it can save clean water and reduce the amount of sewage。

3.4、Bleaching section: It can be used as a high concentration reactor to complete the high concentration mixing of slurry and bleaching solution. It has the advantage of rapid bleaching under high concentration. And can save bleach and other chemicals。

Due to the different design principles of the equipment, the reduction of fiber length in the pulping process of the double-screw kneading separator is much less than that of disc refiner, but it has excellent destructive effect on fiber primary wall (P layer) and secondary wall outer layer (S1 layer), which is beneficial to pulping and improving paper quality.

四、Characteristics of twin-screw kneading and separating machine:

4.1、The twin-screw kneading and separating machine can replace the traditional pulping and bleaching process and complete the processes of impregnation, cooking, bleaching, grinding and washing.

4.2、The concentration in the refining area of the equipment is as high as 25%-40%, which belongs to high consistency refining. When grinding pulp, the fiber cutting effect is small, the fiber after grinding is long and the dewatering speed is fast. The equipment has the function of efficient mixing, the reaction speed of slurry and chemical agents is fast, and the prepared slurry is of high quality.

4.3、The equipment can complete the functions of adding water, dehydration, concentration, washing, discharging waste liquid and adding liquid medicine (or steam) during the grinding process. Therefore, the equipment can be used to complete the functions of impregnation, cooking, washing, bleaching and grinding.

五、Twin-screw rubbing and separating machine Configuration structure diagram