PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

一、Introduction of GNM High concentration Mill:

GNM high concentration grinding is a kind of grinding equipment with screw forced feeding and high concentration grinding.

The equipment has a wide range of uses, and can grind and cook softened wood, bamboo, grass straw, pulp, kitchen waste, seafood fish, shellfish and other materials。 It is an ideal equipment for the treatment of semi-chemical mechanical pulp and pure mechanical pulp in the papermaking process. The feed concentration can reach 20% ~ 50%, saving water consumption and increasing unit throughput.。In the high concentration grinding of straw fiber, due to the low moisture content of the material, the heating rate of the raw material in the grinding process is fast, which is equivalent to realizing a short-time cooking and softening process, and the fiber has a better softness,Therefore, there is little damage to the fiber in the grinding process. It is a necessary equipment in CMP pulping process.

二、Ideal principle of defibering and beating:

In the process of high-concentration pulping, the plant fiber propped up the gap between the two millstones, so that the millstones did not really touch each other. The moving millstones on the spindle had high thrust, which crushed and loosened the fiber at a high speed of 1500 revolutions, so the shear force was reduced, and the fiber was not cut off.。The process of plant straw fibrosis comes from the strong crushing of two grinding discs and the relative rubbing between fibers, which makes the fibers split and broom, and completes the process of defibering and refining。High-concentration refiners have a wide range of applications to materials. No matter wood, bamboo, rice straw, wheat straw, bagasse, waste paper and other raw materials, they can be separated into high-quality fiber raw materials with high linear speed and proper grinding gap.

三、Compared with low consistency refiner, it has obvious advantages:

3.1、Energy saving: the power consumption per ton of pulp is saved by 20%~40%. Saving water: saving water by over 60% per ton of pulp;

3.2、High efficiency: it can improve the physical strength index of fiber by 10%~20%.

3.3、Flexible beating: The raw materials can be crushed, ground, kneaded, etc. in the state of extremely low water content, and the softened and refined straw can be decomposed into better fibers.

3.4、Advantages of high-consistency coarse grinding and shredding: the moisture content of straw raw materials is low, and the temperature rises rapidly under the high-pressure thrust and kneading of two millstones, realizing a short cooking process. At high temperature, the fiber becomes soft and tough and will not be cut. Extruding lignin from fiber can improve fiber quality and reduce the influence of lignin on fiber.

3.5、Lubrication and cooling: it has a unique bearing lubrication and bearing cooling system, which effectively ensures the long-term working conditions of bearings. Ensure that the main engine runs normally for 24 hours and the bearing is trouble-free。

3.6、This machine adopts unique mechanical transmission and hydraulic design, and the precision of the fine-tuning movement stroke of the grinding disc is 0.05mm, with sensitive response. The limit controller ensures that the propulsion gap between the two grinding plates is stable and the grinding plates will not be dry-ground.

四、Table of model and technical parameters of high consistency refiner:

Name Parameter Category | GNM-32 | GNM-36 | GNM-38 | GNM-42 | GNM-44 | GNM-48 |

Grinding disc diameter(㎜) | Ф800 | Ф915 | Ф970 | Ф1060 | Ф1120 | Ф1220 |

Speed of mainshaft(r/min) | 1480-1500 | |||||

Pulpingconcentration(%) | 20-50 | |||||

production capacity(t/h) | 1.5~3 | 2.5~5 | 4~7 | 5~8 | 6~10 | 8~13 |

feed inlet | 500×550 | 500×600 | 600×600 | 800×700 | 800×700 | 900×800 |

Discharge hole(㎜) | 680×170 | 680×210 | 700×210 | 710×210 | 710×210 | 850×250 |

Moving stroke of grinding disc(㎜) | 0-40 | 0-50 | 0-50 | 0-50 | 0-50 | 0-50 |

Cooling water Pressure(mpa) | 0.3~0.35 | |||||

Cooling water flow(L/min) | 200-300 | 200-300 | 300-400 | 300-400 | 300-400 | 300-500 |

Main motor power(kw) | 280-355 | 500、630 | 630、800 | 1250 | 1800 | 2000 |

Feeding motor(kw) | 7.5 | 11 | 15 | 18.5 | 22 | 22 |

Overall weight(㎏) | 8300 | 14000 | 150000 | 17800 | 21000 | 24000 |

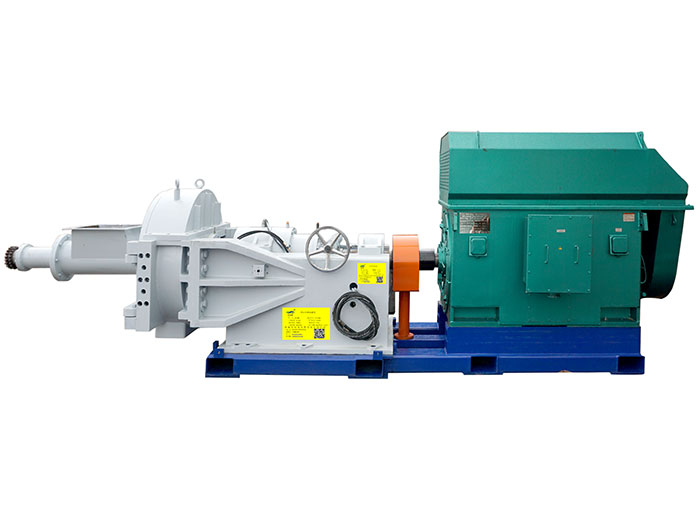

五、Physical appearance structure diagram of the equipment:

The pulping method adopts chemical pretreatment and mechanical grinding post-treatment. First, mild pretreatment (impregnation or steaming) is carried out with chemicals to remove some hemicellulose from the wood chips. Lignin is less dissolved or hardly dissolved, but softens the intercellular layer. After further processing by a disc mill, the softened wood chips (or grass chips) are ground to separate the fibers into pulp, abbreviated as CMP.