PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

一、Overview of Upflow Pressure Screen:

SLS upflow pressure screen is a new type of energy-saving and efficient pulp screening and purification equipment. Compared with high consistency pressure screen and downflow pressure screen, the energy saving is more than 10%. According to the characteristics of impurities in pulp, we design an upflow screening structure, which is widely used in pulp screening systems of major paper manufacturers, with good operation stability and reliability.

二、principle of operation:

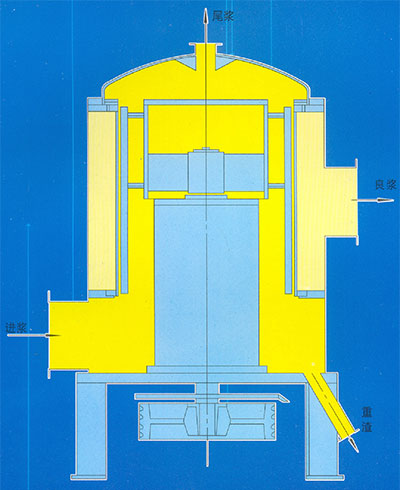

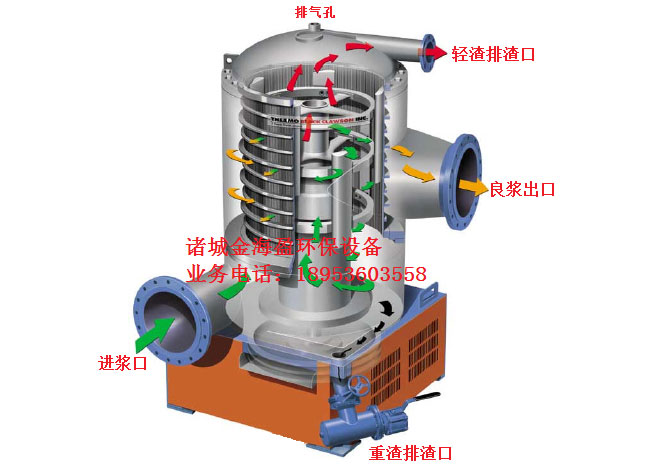

As we all know, the impurities in recycled pulp are divided into light impurities and heavy impurities. The traditional pressure screen is fed from the top and discharged from the bottom, and light and heavy impurities pass through the whole screen pulp area. Because the recycled waste paper box pulp will contain many hard impurities such as nails, spindle box nails, sand and gravel, when these impurities pass through the screening area, it will inevitably cause serious wear and damage to the screen drum and rotor.Serious will break the sieve drum.

SLS-type upflow pressure screen adopts the upflow structure design of feeding slurry at the bottom, discharging heavy slag at the bottom and discharging light slag at the top, which effectively solves the above problems。As soon as the heavy impurities enter the machine body, they are thrown to the bottom sediment tank and discharged from the machine intermittently or continuously through the heavy slag discharge pipe, while the light impurities rise to the top slag discharge port under the pressure. In this way, on the one hand, the residence time of impurities in the screening area is effectively shortened, the possibility of impurity circulation is reduced, and the screening efficiency is improved; On the other hand, it can prevent heavy impurities from damaging the rotor and screen drum and prolong the service life of the equipment.

三、Model technical parameter list:

Name Parameter Category | SLS0.6 | SLS0.8 | SLS1.2 | SLS2 | SLS3 | SLS4 |

Sieve size mm | Φ1.1-Φ3 | |||||

Screen seam size mm | H0.1-1 | |||||

Filter Area m2 | 0.6 | 0.8 | 1.2 | 2 | 3 | 4 |

Screen drum specifications | Φ600×355 | Φ600×445 | Φ600×648 | Φ756×838 | Φ756×1048 | Φ756×1048 |

Inlet and outlet slurry concentration% | 0.8-1.5 | 0.8-1.5 | ||||

Inlet diameter mm | Φ200 | Φ250 | Φ300 | Φ325 | Φ400 | Φ450 |

Diameter of slurry outlet mm | Φ200 | Φ250 | Φ300 | Φ325 | Φ400 | Φ450 |

Top slag discharge diameter | Φ80 | Φ80 | Φ100 | Φ125 | Φ125 | Φ125 |

production capacity T/D | 20-30 | 30-40 | 40-80 | 100-190 | 160-280 | 200-400 |

Originally equipped with power | ||||||

power KW | 37/4 | 45/4 | 55/4 | 110/4 | 160/4 | 200/4 |

Speed r/min | 560 | 540 | 520 | 450 | 300 | 300 |

Improved equipped with power (low water resistance anti winding drum rotor) | ||||||

动力 KW | 22 | 30 | 37 | 55 | 90 | 132 |

Note: The equipment adopts a drum rotor with low water resistance and anti winding type, so the resistance is small and the power consumption is low. Large production capacity. | ||||||

Low water resistance anti winding drum pressure screen rotor: