PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

1、 Overview

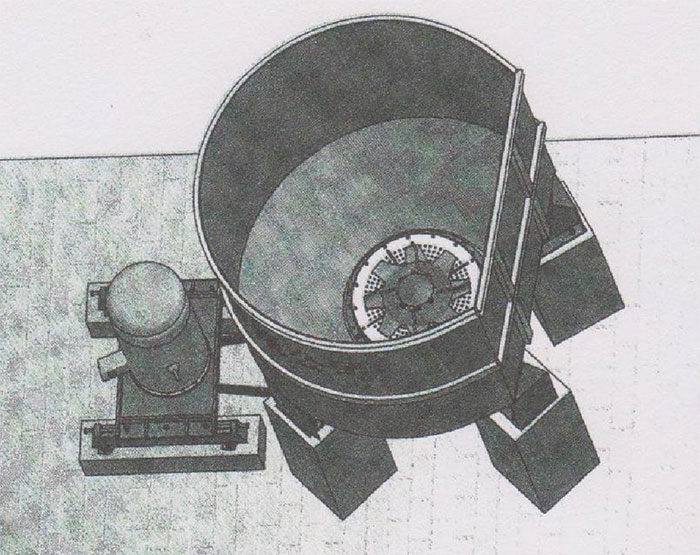

The D-type hydraulic pulper is mainly used for crushing various waste OCC, domestic waste cardboard boxes, pulp boards, damaged paper, and various types of waste paper.

2、 Composition structure:

The D-type hydraulic pulper is mainly composed of D-type tank body, rotor and pulp tray, bracket, motor and protective cover.

3、 Principle of pulping program:

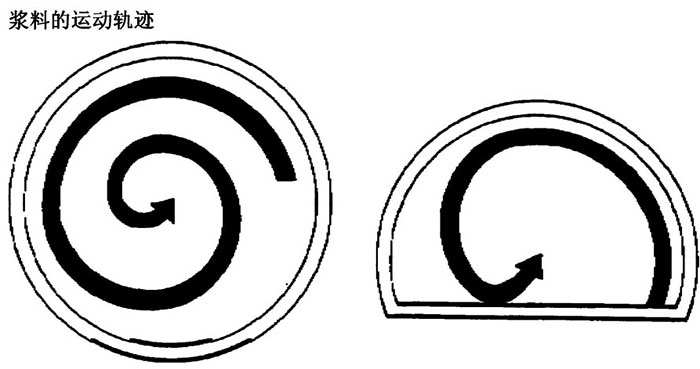

When the pulper tank is filled with 1/2 of water, the motor is started, and the pulp board, damaged paper or waste paper is evenly fed into the tank. When the rotor rotates, the pulp is thrown out from the center to the surroundings, generating a vortex at its center. The pulp is subjected to strong hydraulic impact and shear action, producing intense friction and soft rubbing with each other. At the same time, due to the impact of the rotor, the pulp board and damaged paper are broken down in a wet state, dissociated into single fibers, and the separated pulp flows out through the sieve holes. Foreign objects and heavy slag are collected in the settling tank and discharged regularly; During continuous operation, foreign objects and heavy slag enter the sediment well and are discharged after being treated by the impurity separator. Due to the special structure of the tank body of this series of hydraulic pulpers, when the rotor rotates, the slurry flow is blocked by the D-shaped straight surface of the tank body and bends towards the center, shortening the rotation path of the slurry and increasing the frequency of slurry fragmentation. The unbroken paper and fiber bundles are further loosened in the gap between the rotor and the sieve plate. Due to the special shape of the tail of the broken blade, it has the function of keeping the sieve holes unobstructed. When shredding waste paper, a winch is equipped to continuously remove tangled impurities, which can greatly extend the continuous operation time of the pulper and improve work efficiency.

1. D-type groove body:

Made of welded steel plates, the upper opening is reinforced with channel steel on the outside, and a guide plate is installed inside the conical bottom to allow the slurry to flow back and form a circulation. At the bottom of the tank, there is a rectangular interface connected to the sediment well, which is opened by the user on site according to the process requirements.

2. Rotor device:

Including rotor, sieve plate, slurry tray and transmission device. The rotor is a Vox energy-saving rotor made of cast steel. The blades are made of tool steel and have undergone heat treatment. The blades are fastened to the rotor blades with screws and can be replaced after wear. The material of the sieve plate is wear-resistant stainless steel, with a bottom blade embedded on it. The gap between the bottom surface of the rotor blades and the bottom blade of the sieve plate is initially set at 2mm, which can be adjusted with adjusting bolts as needed.

The rotor and the slurry tray are raised above the bottom of the groove, forming a low-pressure zone around the slurry tray to gather impurities. Impurities are carried into the sediment well by the slurry flow and continuously separated; On the other hand, it can reduce the contact between impurities and the rotor, extend the service life of the rotor, and prevent the rope from winding around the rotor for normal operation. There is a good slurry outlet pipe under the slurry tray, which can be connected to the slurry pump.

3. Bracket:

Made of welded steel plates, used to support the groove body and rotor device. Crushers with a capacity of 20m3 or more (including 20m3) can generally be equipped with a winch and a sediment well. The winch can remove tangled impurities such as plastic packaging bags, rope heads, iron wires, etc. The bottom of the crusher tank has a rectangular interface to achieve continuous production, and heavy debris deposited at the bottom of the sediment well is discharged regularly. This interface can also achieve intermittent production by only balancing the slag collection tank.

The comparison between the paper movement path in the D-type pulper and the traditional pulper is shown in the following figure:

3、 Specification parameters:

model | ZDSⅡ5 | ZDSⅡl0 | ZDSⅡ15 | ZDSⅡ20 | ZDSⅡ25 | ZDSⅡ30 | ZDSⅡ40 | |

Nominal volume m3 | 5 | 10 | 15 | 20 | 25 | 30 | 40 | |

Pulp concentration % | 3-5 | |||||||

production capacity t/d | 20-40 | 60-80 | 80- 120 | 140-180 | 180-230 | 230-280 | 300-370 | |

Mesh size specification mm | φ10-φ24 | |||||||

Equipped with motor | model | Y315M-6 | Y315M-6 | Y355M1-6 | Y255M2-6 | Y355L1-6 | Y400-8 | Y355-4 |

power | 75 | 110 | 160 | 185 | 220 | 280 | 355 | |

voltage | 380 | |||||||

External dimensions(1×W×h) | 4600×3200×4000 | 4800×3800×4200 | 5080×4935×4200 | 5000×4000×4600 | 5350×4400×4875 | 6500×5010×4760 | 5200×5600×5800 | |

Equipment weight kg | 6000 | 7200 | 8920 | 11000 | 13000 | 19500 | 25500 | |

Note: The production capacity in the table is determined under the conditions of equipped sediment wells, impurity separators, continuous crushing of AOC raw materials, and operating temperatures greater than 60 degrees Celsius.