PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

1、 Overview:

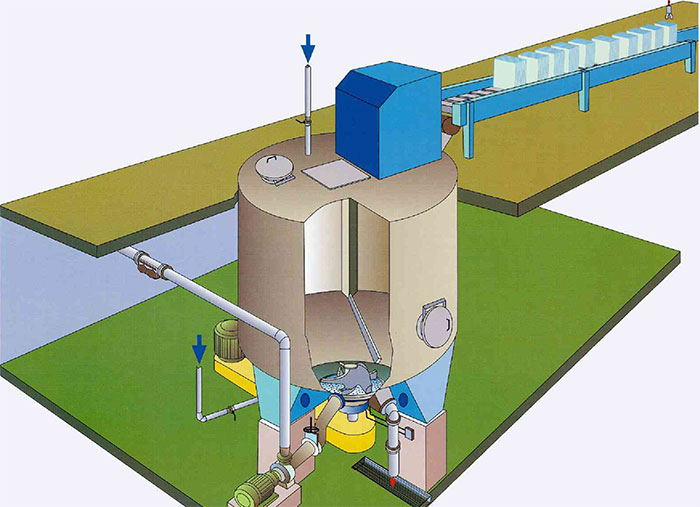

Medium concentration hydraulic pulper is suitable for the crushing and pulping equipment of waste paper with high wet strength and difficult to crush. The mechanical force of hydraulic shearing and pulping impellers is used to break, disperse, and hydrate paper.

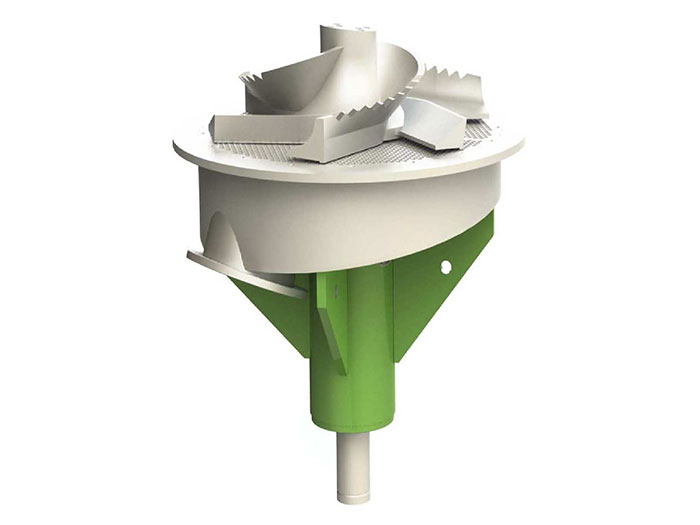

The medium strength pulper is made of steel barrels and has a vertical structure. An impeller for shredding cardboard is installed at the vertical center position. The impeller drives the water flow to form a strong vortex during high-speed rotation, causing the hydraulic vortex to shear the cardboard strongly. The high-speed rotation of the impeller has a strong impact on the cardboard, causing scratches, breakage, and other effects. Combined with the friction cutting effect of the bottom sieve holes, it accelerates the thinning and hydration of the cardboard. Complete the pulping process.

The paper material that needs to be shredded is fed into the circular opening above, usually using a forklift or conveyor belt. It can be fed into whole packaged waste paper or loose materials, but must be unbound with wire, mesh, ropes, and other packaging materials. To avoid entanglement and damage to the equipment. The concentration of equipment fragmentation is generally controlled between 6% and 10%, and is not easily too high. The slurry vortex is a cyclic process that sinks from the center and spreads outwards. When the rotor is running at high speed, the central liquid is quickly sucked into the bottom, strongly collides with the impeller, and is quickly thrown towards the cylinder, where it interacts with the slurry stopper on the inner wall of the cylinder to produce a tangential release, friction, and crushing effect, accelerating the crushing, release, and hydration of the cardboard. Waste paper is always in a high concentration state and undergoes rapid friction, resulting in strong friction and rubbing between fibers, as well as strong friction between the tearing teeth and the fins, ultimately completing the process of breaking the cardboard.

2、 The characteristics of this series of devices include:

1. It can crush waste paper in a high concentration state of 6% -10%, and flexibly release and protect the fiber strength of recycled pulp.

2. For mixed waste paper containing a large amount of impurities (such as plastic, metal sheets, gravel, etc.), it is not easy to break the impurities, which is beneficial for the screening and purification of subsequent processes.

3. It can achieve continuous feeding and continuous slurry production procedures, and can also use intermittent batch pulping method, with good pulping effect and fast speed. Save electricity and heat, and reduce the amount of chemicals used.

3、 Model and parameter table of medium concentration hydraulic pulper:

model | ZNS-5 | ZNS-8 | ZNS-10 | ZNS-15 | ZNS-20 | ZNS-25 | ZNS-30 | |

Nominal volume m3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | |

Pulp concentration % | 6-10 | |||||||

production capacity t/d | 20-40 | 60-80 | 80- 120 | 140-180 | 180-230 | 230-280 | 300-370 | |

Mesh size specification mm | φ10-φ24 | |||||||

Equipped with motor | model | Y315M-6 | Y315M-6 | Y355M1-6 | Y255M2-6 | Y355L1-6 | Y400-8 | Y355-4 |

power | 75 | 110 | 160 | 220 | 355 | 400 | 500 | |

voltage | 380 | |||||||

External dimensions mm | According to the equipment appearance drawing | |||||||

Equipment weight kg | 4500 | 6200 | 7820 | 8900 | 11000 | 12300 | 15500 | |