PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

一、Introduction of Horizontal desanding and refining equipment:

The horizontal pulp desanding machine produced by our company is an ideal equipment for waste paper recovery, processing and recycling. It has two functions of separating heavy slag (referring to heavy impurities in slurry) and grinding and refining decomposed fiber。The separation principle of heavy slag and pulp is based on the specific gravity difference of metal, sand and fiber。After separating the heavy residue, the pulp enters the mill chamber, and the comprehensive forces such as centrifugal force, crushing force and tearing force produced by the high-speed rotation of the stepped remover are used to further decompose and refine the small pieces of paper in the pulp, so that the single fiber is dispersed to form a fluffy fiber with a broom degree, which increases the bonding force of the paper during copying.

二、Application and characteristics:

The DWSC series horizontal desanding and unbundling machine covers a small area, low maintenance rate, and long service life of the grinding head. It is widely used in the waste paper recycling, papermaking, unbundling and refining process. The main characteristics of this equipment are as follows:

1. The pulp fiber is dispersed completely, the splitting effect is good, and the amount of cutting is very small, which can protect the fiber length after beating and improve the physical strength index of the paper, such as tensile strength and ring compressive strength.

2. It has two functions of separating sand and gravel, metal and dredging broom fiber. One machine can be used in many ways.

3. Since the slurry has removed sand and iron hard impurities before entering the dispersion area, the service life of the rotor and stator is improved. The service life of a set of rotor and stator is more than 2000-5000 hours (corrugated paper, yarn tube paper, board paper, cultural paper and toilet paper are different).

4. The power consumption of tons of dry pulp is about 30 degrees, and the power saving is obvious.

5. The gear grinding of rotor and stator is made of YG-30 high quality hard alloy material (hardness HRA930), which is made by special treatment. High hardness and wear resistance, long service life.

6. The main shaft transmission bearing is lubricating with calcareous oil, good lubrication effect, good heat dissipation and cooling effect. It can meet the needs of continuous work of the equipment throughout the day.

7. It is an ideal equipment for waste paper recycling and pulping, simplifying the production process and reducing the production cost.

三、Advantages of Use:

. The use of this equipment to dredge recycled pulp, can try to keep the recycled fiber is not damaged, not cut off, maintain the length of the fiber, reduce pulp loss! Improve pulp yield! To improve the homogeneous degree of the pulp on the net (Due to the repeated recycling of waste paper, the use of disc grinding pulp to cut off too many fibers, fibers are getting shorter and shorter. In the process of paper making, a large number of fine fibers are lost, resulting in a decrease in pulp yield and an increase in the cost of tons of paper.)"The amount of slurry loss is slightly different according to the raw material, the process, and the Degree of beating."

2. Dispersing is in the shredder large pieces of broken, paper by water soaking softened after dispersing, so that it will be better to keep the length of the fiber is not destroyed, so that the physical indicators of paper better improve. Reduce the fiber damage caused by the forced crushing and cutting of the pulping machine,resulting in the decline of paper tension and ring compression strength, the reduction of folding resistance, the stiffness is not good and soft, which does not meet customer requirements.

3. Remove the hard impurities, avoid excessive impurities in the slurry into the grinding system, resulting in a lot of loss of the grinding disc and excess waste of power, the wear of the impeller and blade of the transmission equipment. "Iron, sand and other hard materials are broken down into fine particles after the number increases more difficult to deal with, resulting in complex slag removal system processes, increased power consumption and other investment and operating costs." More serious is the paper machine mesh cloth and Woolen Blanket, cots and other parts of the damage. There are squeeze , calender rollers, etc. are all affected, and the paper will also cut out small holes to affect sales.

4. The equipment is very suitable for small and medium-sized enterprises, one equipment top two use! It not only removes the complexity of the process, but also saves equipment investment and power consumption

四、main technical parameters:

Model Parameter Name | Inlet diameter | Outlet diameter | production capacity(t/d) | Feed concentration(%) | Pulping pressure | Pressure water | Motor power |

DWSC15N | 100 | 80 | 6-8 | 3-5 |

0.15-0.2 |

0.18-0.25 | 11 |

DWSC20N | 100 | 80 | 10-14 | 3-5 | 15 / 22 | ||

DWSC30N | 100 | 80 | 14-18 | 3-5 | 22 / 30 | ||

DWSC40N | 100 | 80 | 20-25 | 3-5 | 30 / 45 | ||

DWSC50N | 110 | 80 | 25-30 | 3-5 | 37 / 45 | ||

DWSC60N | 125 | 100 | 35-40 | 3-5 | 55 / 75 | ||

DWSC80N | 125 | 100 | 40-50 | 3-5 | 55 / 90 | ||

DWSC100N | 125 | 100 | 45-60 | 3-5 | 75 / 110 | ||

DWSC200N | 200 | 125 | 100-120 | 3-5 | 160 / 200 |

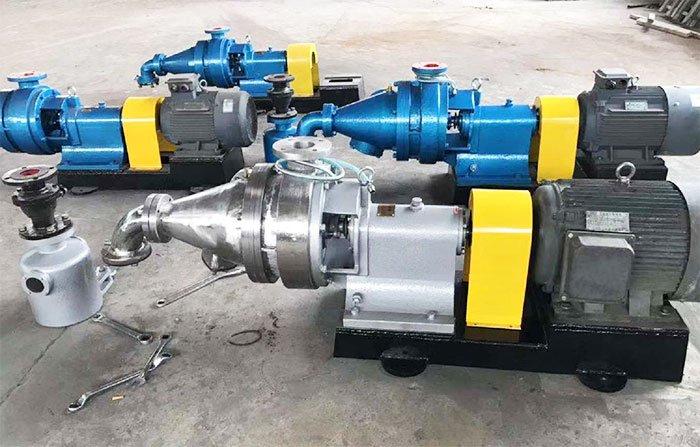

Photo of the structure of the relief grinding head: