PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

1、 Preface

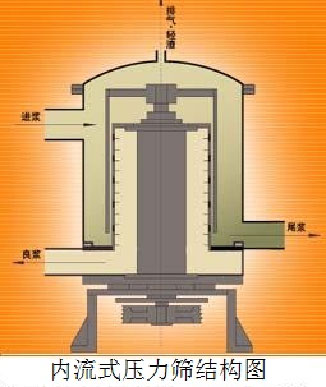

The internal flow external rotor pressure screen manufactured and produced by our factory is an advanced screening equipment in the contemporary paper industry. Suitable for screening waste paper pulp and paper machine screens with high impurities. At present, it is mainly used for dispersing and selecting pulp before paper machines, which plays a key role in improving the sizing uniformity of finished paper. Improve the grade of paper.

2、 Main characteristics of internal flow pressure screen

1. High screening efficiency: The slurry enters the screen at a high pressure tangent and is subjected to centrifugal force. Before entering the screen drum, heavy impurities and coarse fibers have been separated and rotated along the inner wall of the cylinder, slowly settling to the bottom for discharge. Fine and qualified fibers pass through the sieve drum under pressure. Without the interference of coarse fibers and impurities, the throughput of good pulp naturally increases. At the same time, the high-speed rotating blades continuously suck back, playing a role in purifying the surface gaps of the screen drum, allowing the good slurry to pass smoothly. Therefore, under the same conditions of the same power and screening area, this screen has higher screening efficiency and better pulp quality than other forms of screening equipment.

2. Long service life of screen drum: Due to the centrifugal effect, heavy impurities in the pulp are separated after entering the pressure screen, which reduces the impact and wear of coarse impurities on the rotor and screen drum. This extends the service life of the screening drum.

3. Non clogging during pulp screening: The pulp is evenly screened from top to bottom, with almost no thickening phenomenon, and impurities always stay away from the sieve drum, so the sieve drum seams are not easily clogged.

4. Pulse low: After passing through the screening drum, the good pulp is concentrated in the middle of the drum and controlled by the back pressure of the outlet valve. The flow rate instantly slows down, reducing the pulse. Therefore, when used in front of the paper machine net, the good pulp is evenly and stably distributed when directly fed onto the net.

5. Good pulp quality: Excellent internal flow screening structure, low feed pressure, flexible screening, low power consumption, good pulp quality.

6. Easy to maintain: The spindle adopts an advanced mechanical seal system that is not easily damaged, easy to disassemble, and easy to repair, reducing the maintenance burden.

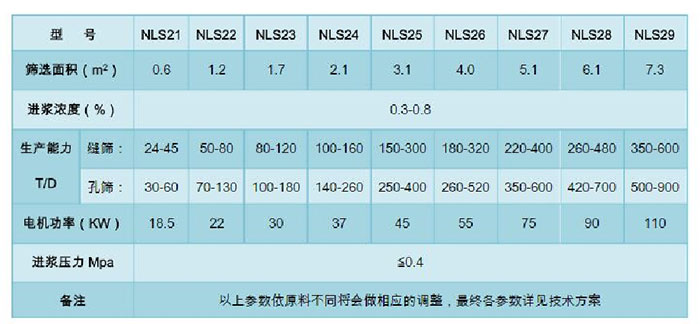

3、 Technical parameters