PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

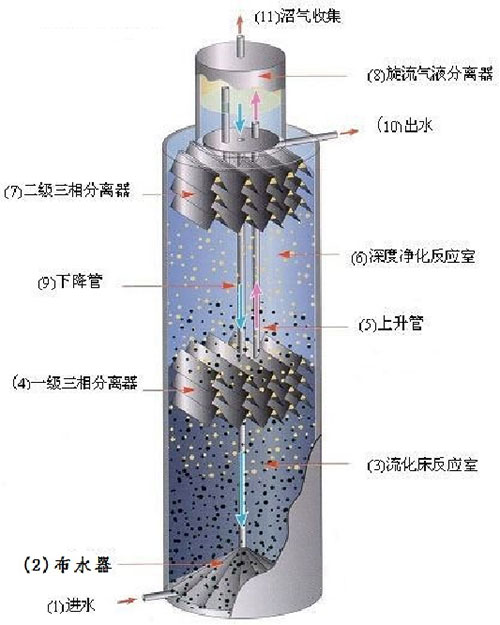

The IC anaerobic reactor equipment is a new generation of high-efficiency anaerobic reactors, namely internal circulation anaerobic reactors. It is composed of two layers of UASB reactors connected in series and is used for organic high concentration wastewater, such as corn starch wastewater, citric acid wastewater, beer wastewater, potato processing wastewater, alcohol wastewater, etc. The IC anaerobic reactor equipment consists of two reaction chambers, with wastewater flowing from bottom to top in the reactor. Pollutants are adsorbed and degraded by bacteria, and purified water flows out from the upper part of the reactor.

The IC anaerobic reactor is currently widely used in the paper industry by paper companies that use various types of waste paper as raw materials. The purpose of treatment includes achieving general standard discharge, reusing treated wastewater, and achieving the dual goals of water conservation and pollution control.

The IC anaerobic reactor, also known as the internal circulation anaerobic reactor, is a third-generation anaerobic bioreactor developed on the basis of UASB reaction. It greatly increases the upward flow rate of sewage through effluent reflux recirculation. The granular sludge in the reactor is always in an expanded state, strengthening the contact and mass transfer between sewage and microorganisms, and achieving high removal efficiency. The height of the reactor is as high as 16-28m. From the appearance, the IC anaerobic reactor is composed of a first anaerobic reaction chamber and a second anaerobic reaction chamber stacked together, with a gas solid liquid three-phase separator installed at the top of each anaerobic reactor. Like two UASB reactors overlapping and connected in series. However, due to the use of a high upstream velocity, there are high requirements for the formation of granular sludge and the pre-treatment of sewage. Granular sludge needs to be added for cultivation and domestication, with high automation requirements, strict management, and relatively high equipment investment.

Compared with second-generation anaerobic reactors, IC anaerobic reactors have the following advantages:

① Has a high volumetric load

IC anaerobic reactors have strong internal circulation, good mass transfer efficiency, and large biomass. Its volumetric load is much higher than that of ordinary UASB reactors, generally about three times higher.

② Save infrastructure investment and land area

The volume load of IC anaerobic reactor is about three times higher than that of ordinary UASB reactor, and it occupies about 1/4-1/3 of the area of ordinary UASB reactor, so it can reduce the infrastructure investment of the reactor. The IC anaerobic reactor is not only small in size, but also has a large aspect ratio, so it occupies a particularly small area and is very suitable for new and expansion projects of factories and mines with tight land requirements.

③ Strong ability to withstand impact loads

The IC anaerobic reactor has achieved its own internal circulation, with a circulation capacity of 10-20 times that of the influent. Because the circulating water and inlet water are fully mixed at the bottom of the reactor, the concentration of organic matter at the bottom of the reactor is reduced, thereby improving the reactor's ability to withstand shock loads; At the same time, the large amount of water also allows the bottom sludge to be evenly dispersed, ensuring sufficient contact and reaction between organic matter and microorganisms in the wastewater, and increasing the treatment load.

④. IC anaerobic reactor has good effluent stability

Because the IC anaerobic reactor is equivalent to the series operation of two UASB and EGSB reactors, the lower reactor has a high organic load rate and plays a "coarse" treatment role, while the upper reactor has a low load rate and plays a "fine" treatment role, resulting in good and stable effluent quality.

In the anaerobic treatment process of wastewater, organic matter in the wastewater is ultimately converted into CH4, CO2, H2O, H2S, NH3, etc. through the joint action of a large number of microorganisms. During this process, the metabolic processes of different microorganisms interact and constrain each other, forming complex ecosystems.

Jinhaiying Environmental Protection Equipment Co., Ltd. can undertake the production, installation, commissioning, and operation of anaerobic reactors such as IC, EGSB, and UASB, which are used in industries such as food fermentation, starch, beer, protein, papermaking, alcohol, and pharmaceuticals.