PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

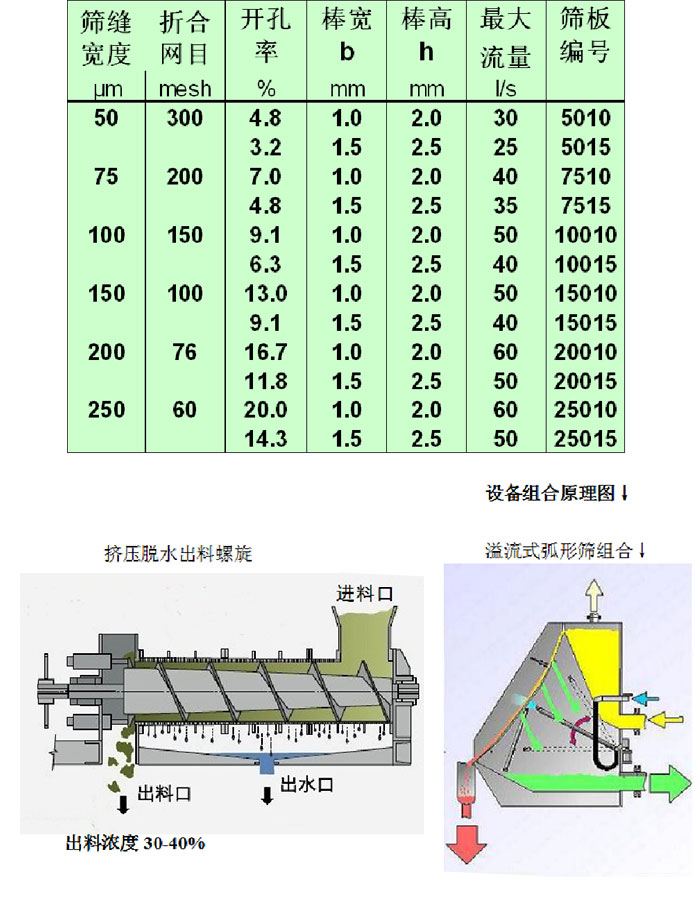

1、 Equipment Introduction:

The DHWL overflow micro seam filter is a solid-liquid separation equipment that uses a seam shaped screen grid as the filter body. The screen grid is made of imported materials such as 304 or 316L stainless steel, Hastelloy alloy, etc., and is welded with drawn triangular bars. It has high hardness, wear resistance, high-precision processing of gaps, high filtration accuracy, and large throughput. The back of the sieve plate is equipped with high-pressure backwash water, which intermittently cleans the sieve plate according to the set time to ensure smooth water filtration and prevent material blockage. There are two types of backwash nozzles, ceramic and stainless steel, with a fan-shaped spray structure to ensure coverage for spray washing. The equipment casing, side plates, pipelines, and flanges are all made of 304 stainless steel. For special water quality requirements with high corrosion resistance, they can be customized according to customer requirements.

3、 Introduction to characteristic principles:

The working principle of the DHWL overflow micro seam filter is that the mixed liquid that needs to be filtered is pumped into the buffer stabilizing tube of the equipment through a liquid level height or low head water pump. After adjusting the stable flow, it overflows onto the screen grid through the overflow weir. With the help of its own weight, the water is cut and filtered layer by layer by the high-density screen grid when the liquid falls, penetrating the screen plate and separating from the raw material. Achieve the goal of filtration and separation. Solid matter is trapped on the surface of the sieve, and with the lubrication of the liquid, it rolls down. The sieve is constantly washed away by the liquid, causing the surface of the sieve to perform self-cleaning, thus completing the entire process of continuous self-cleaning of the sieve and continuous collection of solid matter. The material collected on the surface of the sieve is discharged from the discharge port at the bottom of the front. Depending on the type of material and the water content requirements of the discharge, the solid material discharge port can be connected to a belt type or spiral extrusion dewatering equipment for forced pressure dewatering.

4、 Application scope:

1. Fiber recycling in the pulp and paper industry, white water purification in paper machines, solid-liquid separation, and pulp concentration and dehydration.

2. Fine filtration in the sewage treatment industry filters fine fibers, fur, feces, oil, down residue, mud and sand particles, plant residues, etc. from sewage. The slag outlet can be equipped with a compression screw to make the discharge drier and facilitate transportation and disposal.

3. Solid liquid separation in the food and pharmaceutical industries has a wide range of applications and is welcome to be purchased.

5、 Structural schematic diagram

6、 Photos of on-site and workshop production equipment used: