PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

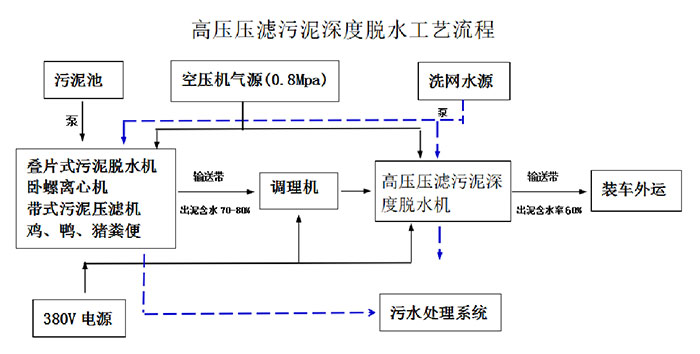

1、 Introduction to high-pressure filter press sludge deep dewatering machine:

2、 Economic benefit analysis:

Due to the high moisture content of the sludge produced by ordinary belt filter presses, laminated sludge dewatering machines, and horizontal screw centrifuges, which is generally between 70% and 85%, the transportation and disposal costs of sludge are too high. In order to reduce the disposal cost of sludge and improve combustion value, deep dewatering is necessary, including plate and frame filter press (sludge concentration of about 40%), and further deep pressing dewatering. After passing through the high-pressure filter press, the sludge concentration can reach between 40% and 52%, depending on the type of sludge. Significantly reduce transportation and disposal costs.

3、 The benefits of using a high-pressure filter press sludge deep dewatering machine:

1. After deep dewatering of high-pressure filter press sludge, the moisture content of the sludge is uniform, and the moisture content of any part is almost the same. The dewatering process of plate and frame filter press relies on screw pump or diaphragm pump, and the sludge is transported under high pressure, so the moisture content of the sludge in the middle channel is high.

2. The production capacity for continuous work is high, but the labor force is small and does not require dedicated supervision. Save on salary expenses.

3. After the sludge is discharged from the belt filter press and laminated sludge dewatering machine, it is directly sent to the equipment for pressing and dewatering by the conveyor belt without the need for additional chemicals. Deep dehydration, cost saving, significant effect!

4. The sludge concentration is as high as 40-52%, and the sludge output is more than 5 percentage points higher than that of the plate and frame sludge filter press on average. Moreover, the moisture content is balanced, and the receiving unit randomly inspects the sludge, and the measured moisture content values are almost the same. This is something that plate and frame filter presses cannot achieve. (Because the inlet of the plate and frame filter press is pressurized by a high-pressure pump, the inlet channel and the middle sludge have high moisture content, and the moisture content on both sides of the filter cloth is low, commonly known as the sandwich biscuit structure).

4、 The structural principle of high-pressure filter press sludge deep dewatering machine:

The high-pressure filter press sludge deep dewatering machine is an improved product developed on the basis of the original double mesh belt filter press. The working principle is to wrap the filter belt and material with steel strips, and use the steel tensile strength of the steel strips to apply strong wrapping and squeezing pressure to the material in the belt, forcing material dewatering. The principle is similar to holding an object with your hand and squeezing it. Ensure that the sludge will not collapse or escape. According to the type of sludge and the required dryness, one to three stages of steel belt pressure dewatering process can be set up.

5、 Equipment Model Parameter Table:

model | bandwidth | power | Filter belt cleaning water | Gas source | Entering the mud concentration (%) | Mud release concentration (%) | Mud output after dehydration | |

water pressure | amount of water | pressure | ||||||

DGWT750 | 750 | 2.2 | 0.4 | 50 | 0.8 | 15-30 | 40-52 | 0.4-0.7 |

DGWT1000 | 1000 | 3 | 0.4 | 60-70 | 0.8 | 15-30 | 40-52 | 1.2-2.4 |

DGWT1500 | 1500 | 4 | 0.4 | 90-100 | 0.8 | 15-30 | 40-52 | 1.8-4.5 |

DGWT2000 | 2000 | 5.5 | 0.4 | 100-120 | 0.8 | 15-30 | 40-52 | 2.5-6 |

DGWT2500 | 2500 | 11 | 0.4 | 130-160 | 0.8 | 15-30 | 40-52 | 3-7.5 |

DGWT3000 | 3000 | 15 | 0.4 | 180-200 | 0.8 | 15-30 | 40-52 | 4-7.2 |

6、 On site equipment photos: