PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

1、 Overview:

Wherever there is a population living, pollutants are generated, whether in daily life, industrial production, etc., as long as water is used, sludge pollution will be produced. With the improvement of human living standards, pursuing green ecology and environmental sanitation is everyone's dream. So we must treat the sewage and sludge generated in our daily lives, solve these pollutants, and maintain ecological balance.

2、 Principle of sludge dewatering:

The water containing sludge is separated and transported to the sludge mixing tank by a sludge pump. At the same time, a coagulant is added for thorough mixing reaction. The coagulant is a high molecular polymer that has the functions of bridge, net capture, adsorption and electrical neutralization when the sludge slurry is mixed. Then it flows into the sludge distributor of the belt sludge filter press, and the sludge is evenly distributed on the gravity dewatering zone. Under the bi-directional guidance of the sludge rake and the action of gravity, the sludge quickly removes the free water of the sludge with the movement of the dewatering filter belt. Due to the long design of the gravity dehydration zone, maximum gravity dehydration is achieved. The flipped sludge enters the ultra long wedge-shaped pre pressure dewatering zone to slowly clamp the sludge unloaded from the gravity zone, forming a sandwich shaped angle layer. It is sequentially and slowly pre pressurized and filtered to minimize the residual free water in the sludge layer. As the upper and lower filter belts slowly advance, the distance between the two filter belts gradually decreases, and the middle sludge layer gradually becomes hard. Through the pre pressure dewatering large-diameter filter roller, a large amount of free water is removed, and the sludge cake smoothly enters the extrusion dewatering zone and enters the "S" pressing section. In the "S" pressing section, the sludge is sandwiched between the upper and lower filter cloth layers, and is repeatedly pressed by several pressing rollers. When the belt passes through the waveform path formed by the staggered rollers, shear force is generated on the clamped mud cake due to the alternating vertical positions of the two filter belts, The majority of the remaining water in the sludge is accumulated and filtered out, causing the sludge cake to dehydrate again. Finally, the dry sludge cake is scraped off by a fiber scraper and transported to the sludge storage area by a belt conveyor or a shaftless screw conveyor.

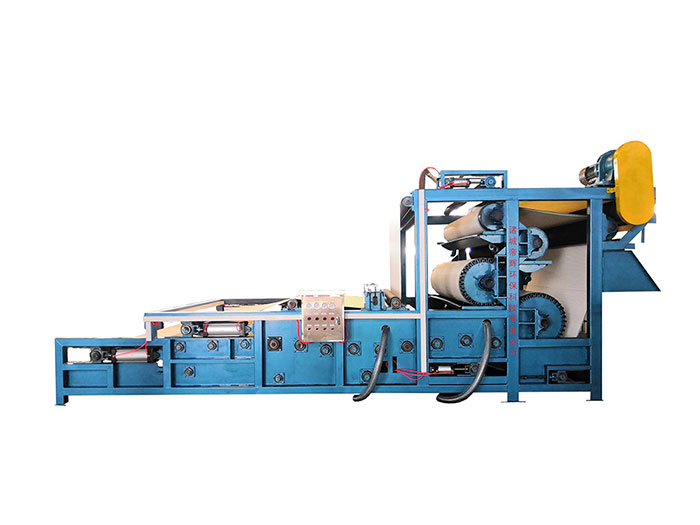

3、 The composition of the triple belt sludge filter press:

The belt type sludge dewatering machine consists of a filter belt, a roller press cylinder, a filter belt tensioning system, a filter belt deviation adjustment system, a filter belt flushing system, and a filter belt drive system. Belt sludge dewatering machines are divided into four categories: universal belt sludge dewatering machines, strong belt sludge dewatering machines, ultra strong belt sludge dewatering machines, and heavy-duty belt sludge dewatering machines used in industrial production.