PRODUCT

Dihui Environmental Protection

- contacts:Mr. Zhang

- Tel:177-5364-5188

- Add:No. 118, Houhuangtuan Village, Mizhou East Road, Mizhou Street, Zhucheng City, Weifang City, Shandong Province, 178 meters north of Houhuangtuan Industrial Park

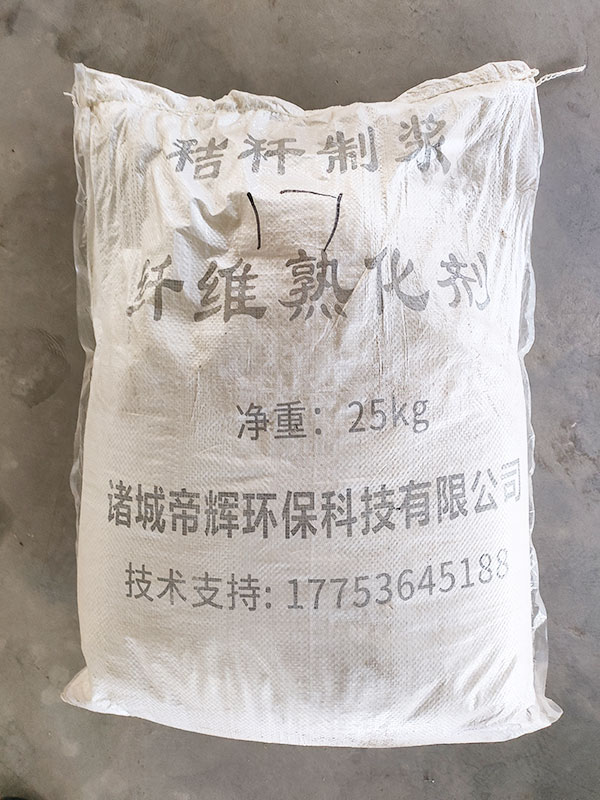

1、 Product Name: Straw Fiber Maturing Agent

2、 Product characteristics: granular powder (or liquid)

3、 Attention:

This additive has a certain degree of corrosiveness and needs to be stored in a cool, ventilated, and dry place. Do not get damp and harden. Pay attention to the outer packaging bag to prevent it from breaking, and do not place it together with items that are afraid of corrosion. Protective clothing and gloves are required for handling operations. After melting, there is a burning sensation when in contact with the skin, which can burn the skin for a long time. It is necessary to rinse with water as soon as possible. If accidentally splashed into the eyes, rinse with water as soon as possible or seek medical attention for rinsing treatment as soon as possible.

4、 Softening operation method of wheat straw fiber:

Add 3% -5% of dried wheat straw according to the measurement (double the amount for liquid)

160kg Wheat Straw Additive Addition and Usage Method:

Usage: After being cut into sections (3-5cm) by a grass cutter and dust removed, wheat straw is disassembled and kneaded by a straw dismantling machine to break down the circular straw, remove the wax film on the surface, and expose the white film inside the straw. It is then separated by a cyclone separator for dust removal. Both the internal white film and the surface wax film have waterproof properties. Without the aforementioned equipment, prolonged soaking is required. If using the long-term soaking method, please dilute the auxiliary agent 30 times before use. Alternatively, according to the ratio of additives added and calculated based on the forage, use it in a ratio of wheat straw: water, 1:1-1.5. After being evenly soaked, it can be heated and steamed for 60-120 minutes, which can be divided into two stages: the first 60 minutes, followed by rough grinding and then another 60 minutes of reaction. If the fermentation reaction is carried out using the same method, the moisture content should not exceed 60%. At this time, the stacking heating rate is fast and the fermentation temperature is high. High moisture content affects the stacking effect. Stacking must be left for at least 24 hours. It is recommended to adopt the heating continuous production method for regular production, with balanced temperature and time, and stable quality. If the quality of the fiber products produced does not meet the standards, please increase the proportion of additives as appropriate, and the maximum amount should not exceed 5%. The normal production temperature is between 120-100 degrees Celsius for steam.

The first steaming time is 60 minutes, and the second insulation time is 60 minutes.

The effect of kneading wheat straw is shown in the following figure: